How Does Airless Packaging Technology in Lip Gloss Pens Extend Product Shelf Life?

Dec 09, 2024

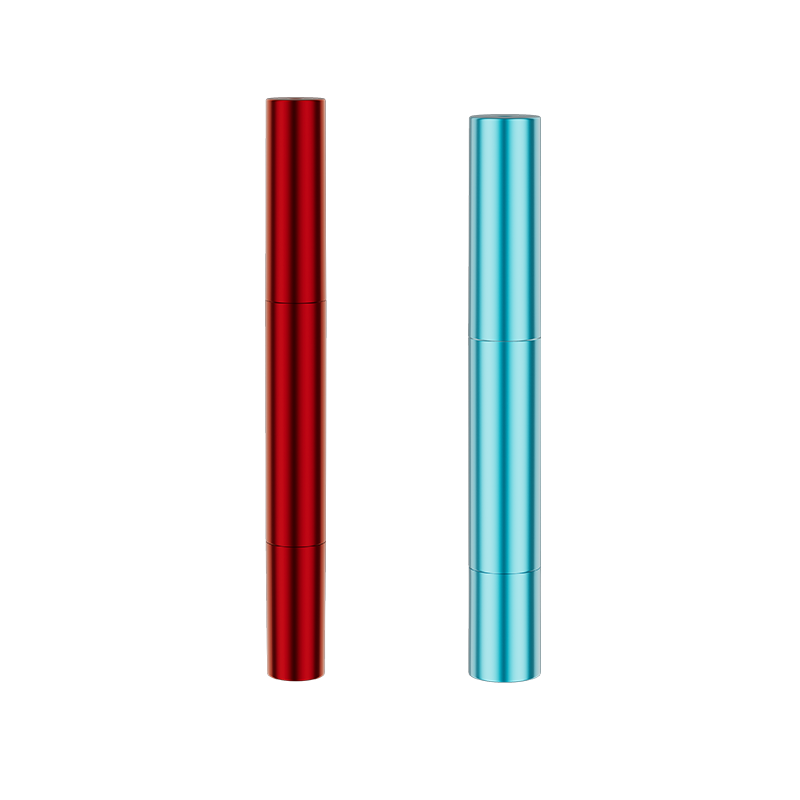

In the cosmetics industry, packaging plays a critical role not only in aesthetics and convenience but also in preserving product quality. For packaging products like lip gloss pens, airless packaging technology is widely used to ensure the product remains stable after opening, protecting it from oxidation, contamination, and degradation. This article will explore how airless technology in lip gloss pen packaging helps extend product shelf life and maintain its quality.

1. What is Airless Packaging Technology?

Airless packaging technology refers to a design that prevents the product from coming into contact with air, typically using a vacuum pump or piston mechanism. This packaging creates a sealed environment inside the container, preventing external air, oxygen, moisture, and bacteria from entering. In the cosmetics industry, airless packaging has become a common solution for reducing oxidation and contamination, ensuring longer product stability and a fresher user experience.

2. Preventing Oxidation and Degradation

Lip gloss pens usually contain ingredients that are prone to oxidation, such as natural oils, vitamin E, and certain pigments. When exposed to air, these components can degrade, causing the product to lose its color, consistency, or even develop unpleasant odors. Airless packaging helps by creating a vacuum inside the container, which prevents oxygen from entering and reacting with the ingredients, thereby reducing the chances of oxidation.

The airless system also helps maintain the glossiness and texture of the product. Oxidation can cause lip gloss to darken or lose its smooth finish, but airless packaging keeps the product sealed and protected, ensuring that it remains stable and effective for a longer period.

3. Preventing Bacterial Contamination

One of the most significant advantages of airless packaging is that it minimizes the risk of bacterial contamination. Traditional packaging with open containers or pumps allows air and external contaminants to enter the product, especially when fingers or applicators come into contact with it. This exposure can introduce bacteria, dust, and other pollutants that can lead to spoilage or skin irritation.

Airless packaging, on the other hand, uses a closed system to protect the contents. The user interacts with the pump or nozzle, without ever touching the product inside the container. This prevents bacteria or other contaminants from entering, ensuring the product remains hygienic throughout its lifespan.

4. Preventing Evaporation and Ingredient Loss

Airless packaging also helps retain volatile ingredients such as alcohol, fragrance, and water-based components, which are common in lip gloss formulations. These ingredients can easily evaporate when exposed to air, causing the product to dry out or lose its intended effect. With airless technology, the product remains sealed, preventing these volatile components from escaping, and ensuring that the lip gloss stays fresh and effective.

By reducing evaporation, airless packaging helps extend the shelf life of the lip gloss and preserves the quality of the formula, ensuring that each application provides the same smooth, glossy finish as the first use.

5. Enhancing Convenience and Hygiene

Beyond product preservation, airless packaging also improves the convenience and hygiene of using lip gloss pens. Traditional packaging often requires opening the cap or using an applicator to access the product, which can lead to exposure to air and potential contamination. Airless packaging eliminates this concern by providing a pump or piston mechanism that dispenses the product without direct contact with the container’s interior.

This sealed, hygienic system ensures that each use is fresh, making it particularly appealing for consumers who prioritize clean and safe beauty products. Additionally, airless packaging often allows for more precise dispensing, helping users control the amount of product dispensed, which reduces waste.

6. Boosting Consumer Trust and Brand Value

Using airless technology in lip gloss pen packaging not only improves the product’s shelf life but also enhances brand image. Consumers tend to trust brands that use innovative and effective packaging solutions, especially when it comes to product quality and safety. Brands that adopt airless technology can signal to customers that they prioritize the integrity of their products, which in turn fosters trust and loyalty.

Airless packaging also aligns with the growing consumer demand for eco-friendly and sustainable products, as many airless systems are designed to be recyclable or made from materials that are more environmentally friendly than traditional packaging.

English

English 中文简体

中文简体