In what specific aspects is the optimization of the pump body structure and air flow channel reflected?

Aug 09, 2024

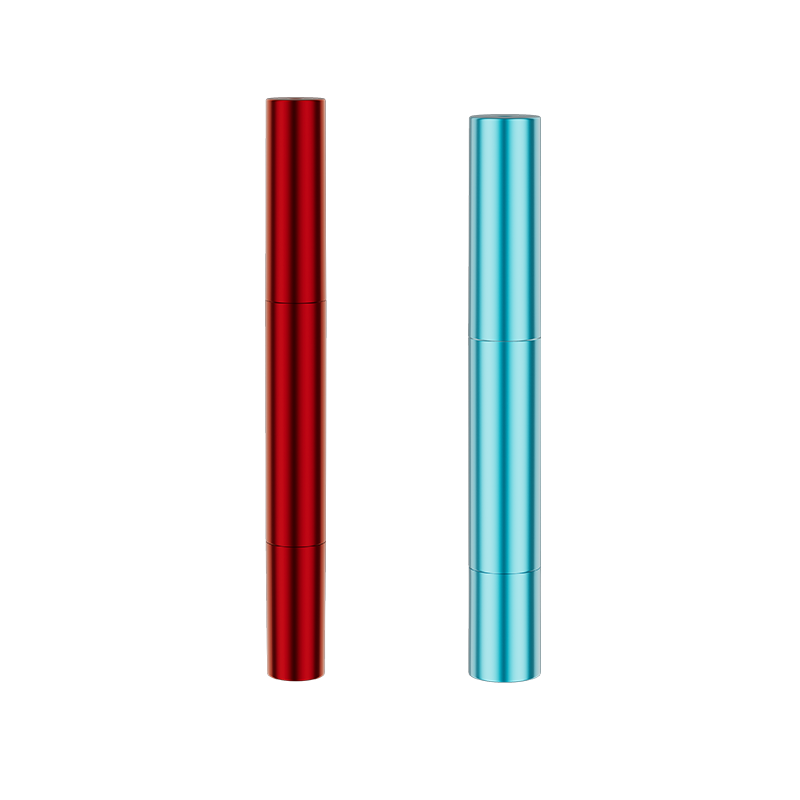

The pump body structure design of the circular refillable vacuum pump tank is the core of its efficient operation. Designers abandoned the single mode of the traditional pump body and adopted a more complex but efficient modular design. This design not only enhances the structural strength of the pump body, but also makes the cooperation between the various components more seamless, effectively reducing the energy loss caused by vibration or impact.

The interior of the pump body is carefully divided into multiple functional areas, each of which has a specific task. For example, the air inlet and exhaust port are cleverly arranged on both sides of the pump body. By optimizing the air flow path, the air flow in the pump body is smoother, reducing the occurrence of eddy currents and turbulence. At the same time, the impeller, piston and other key components in the pump body are also carefully arranged to ensure that the best dynamic balance can be maintained during high-speed rotation or reciprocating motion, further improving the operating stability and reliability of the pump body.

In terms of optimizing the air flow channel, the circular refillable vacuum pump tank also shows extraordinary innovation capabilities. Designers used advanced CFD (computational fluid dynamics) technology to conduct a comprehensive simulation and analysis of the airflow channel in the pump body, identify the key factors that affect the efficiency and stability of the airflow, and make targeted optimization accordingly.

By optimizing the shape, size and layout of the airflow channel, the pump tank successfully reduced the resistance and energy loss of the airflow in the channel. At the same time, the designers also cleverly introduced auxiliary components such as guide plates and vortex suppression devices to further improve the flow state of the airflow, making the air flow in the pump body more uniform and stable. This optimization not only improves the exhaust efficiency of the pump tank, but also significantly reduces the operating noise and vibration levels, bringing users a more comfortable use experience.

Thanks to the optimized design of the pump body structure and airflow channel, the circular refillable vacuum pump tank has achieved remarkable results in improving energy efficiency. First, the application of variable frequency motors enables the pump tank to automatically adjust the speed according to actual needs, avoiding unnecessary energy consumption. Secondly, the use of low friction coefficient materials reduces friction loss between components and further improves energy efficiency. In addition, the introduction of intelligent sleep mode allows the pump tank to automatically enter low power consumption mode in standby mode, thereby maximizing energy utilization.

According to experimental data, compared with traditional vacuum pump tanks, the energy consumption of round refillable vacuum pump tanks under the same working conditions is reduced by about 30%, and the exhaust efficiency is improved by about 20%. This data not only proves the effectiveness of the optimized design, but also brings tangible economic and environmental benefits to users.

English

English 中文简体

中文简体